WHAT WE

MADE HAPPEN

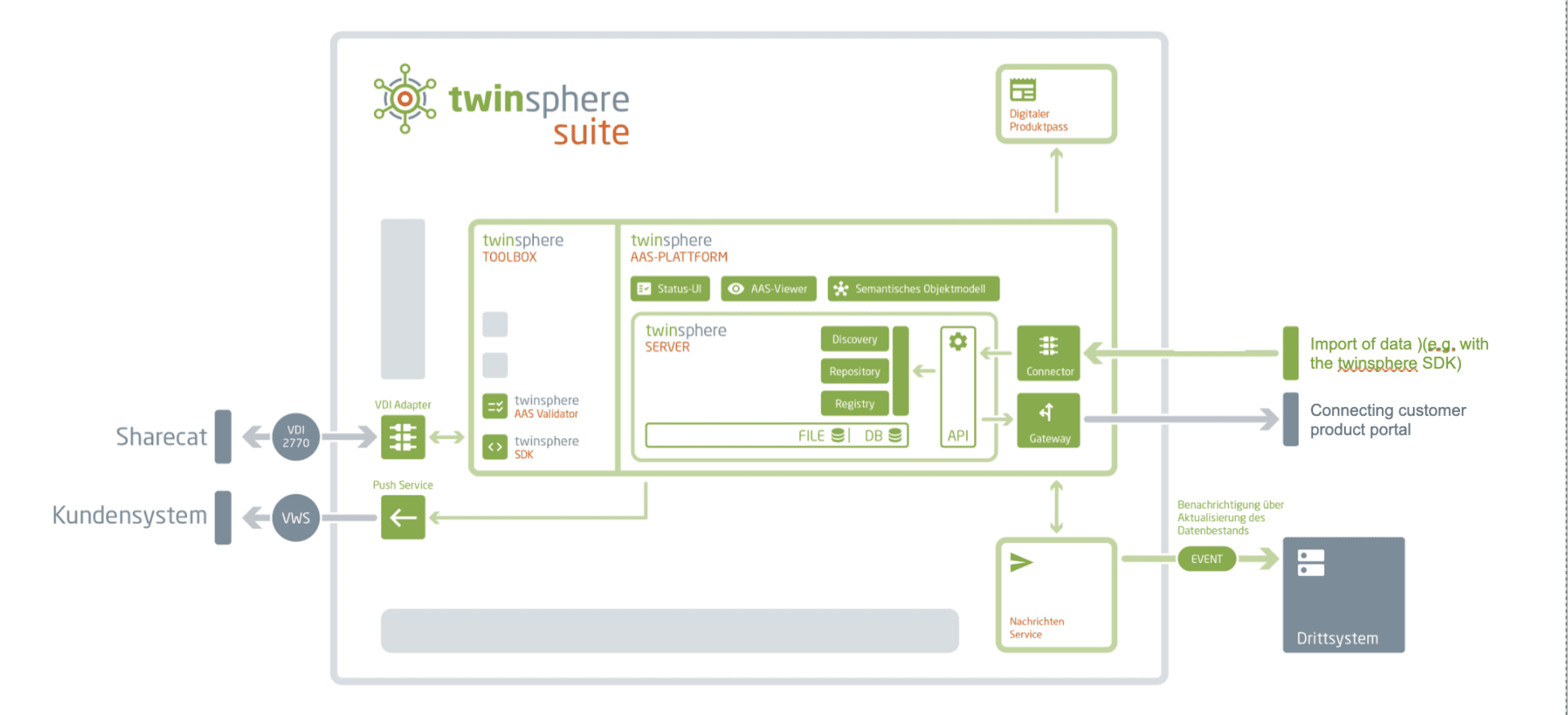

Twinsphere is a scalable, standards-based Software-as-a-Service (SaaS) platform developed by members of the OI4 Workgroup “Component Supplier” to enable the secure creation, management, and utilization of Digital Twins. Built on the Asset Administration Shell (AAS) standard, Twinsphere provides key digital capabilities including support for the Digital Product Passport, seamless data exchange, VDI 2770-compliant document transfer, and integration into ERP, MES, and other third-party systems.

Rather than solving the problem in isolation, the Workgroup pooled resources and expertise from several member companies to create a solution that is both industry-wide and implementation-ready. The result is a modular, cloud-based platform that simplifies the deployment of digital twins while ensuring interoperability and regulatory compliance.

Through this collaboration, medium-sized manufacturers can now access digital services that were previously out of reach. Twinsphere turns complexity into clarity, enabling scalable digital twin rollouts across supply chains, production networks, and customer-facing portals.

The Four Key Use Cases of Twinsphere

Digital Product Passport as a Service

A ready-to-use SaaS platform for creating Digital Twins, reporting the Product Carbon Footprint (PCF), and preparing for the EU’s Digital Product Passport — all aligned with IDTA metamodels and ECLASS classification, and accessible via a standardized API.

Document Transfer According to VDI 2770

Effortless creation and exchange of VDI 2770-compliant document containers using the integrated adapter and PDF/A converter. Ensures smooth handover to platforms like Sharecat and full compliance with DDCC requirements.

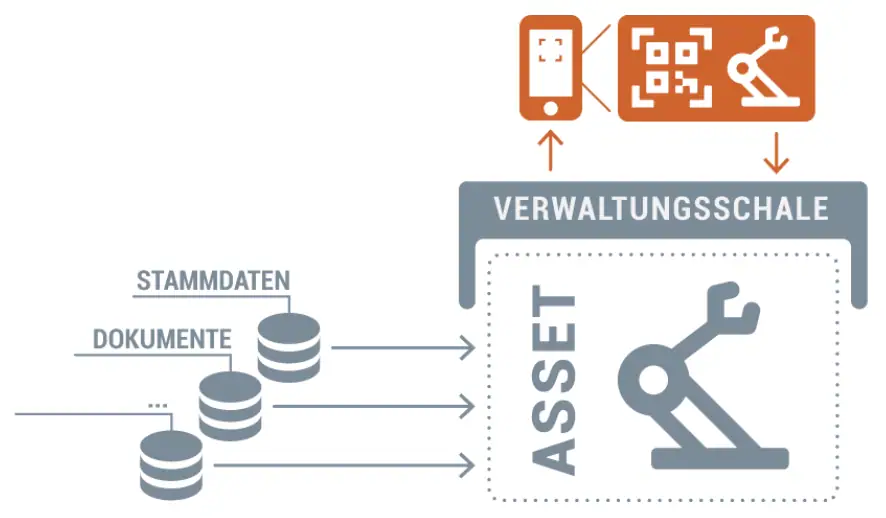

Administration Shells in Third-Party Systems

Host and manage AAS data in a secure, scalable environment with standardized APIs and interactive tools such as the Twinsphere AAS Viewer. Easily integrate into existing systems and enable QR-based user access.

Seamless Value Chain Communication

Provide up-to-date product information and digital nameplates across the supply chain. Notify stakeholders via Messaging and Push Services when new versions, manuals, or digital twins become available.

THE CHALLENGE

WE SOLVED

Industrial manufacturers today operate under growing pressure. Supply chains are fragile. Regulatory demands are increasing. Customers expect connected services and real-time insights. Internally, companies must manage highly complex product data: from specifications and materials to firmware, documentation, and CO₂ emissions.

Twinsphere addresses all of this with one platform. By standardizing access to product and asset data, it closes the gap between engineering, production, and service. And by leveraging the AAS, Twinsphere ensures that data flows securely and consistently across the entire lifecycle of a product, from initial design to end-of-life.

Twinsphere provides:

- A full SaaS platform based on the AAS

- Compliance with IDTA standards and metamodels

- Support for all major AAS APIs and submodels

- Registry, discovery, and repository services

- Software Development Kit (SDK)

- Integrated security and access management

- Scalable cloud infrastructure (Microsoft Azure)

- Optional QR/NFC-based access for end users

- Interactive AAS Viewer for asset navigation

Supported submodels include:

- Digital Nameplate (02006)

- Handover Documentation (02004)

- Technical Data (02003)

- Time Series (02008)

- Contact Information (02002)

- Hierarchical Structures / BoM (02011)

- Carbon Footprint (02023)

WHY THE RESULTS

MATTER (AND FOR WHOM)

Twinsphere transforms how companies manage and share product-related data. Built on the Asset Administration Shell (AAS), the platform enables manufacturers, suppliers, and customers to interact through a shared digital infrastructure, without the need for proprietary integrations or isolated IT systems.

It ensures that the right data reaches the right stakeholder at the right time. Whether for regulatory reporting, product configuration, lifecycle documentation, or after-sales service, Twinsphere provides reliable access to asset data across the entire value chain. This opens up new possibilities for business models such as predictive maintenance, Product Carbon Footprint (PCF) tracking, and the implementation of the Digital Product Passport (DPP).

Medium-sized enterprises, in particular, benefit from the platform’s scalable architecture. It brings digital capabilities that were previously accessible only to larger corporations into reach enabling real-time updates, push notifications, and secure access to multilingual, up-to-date digital twins.

PROJECT

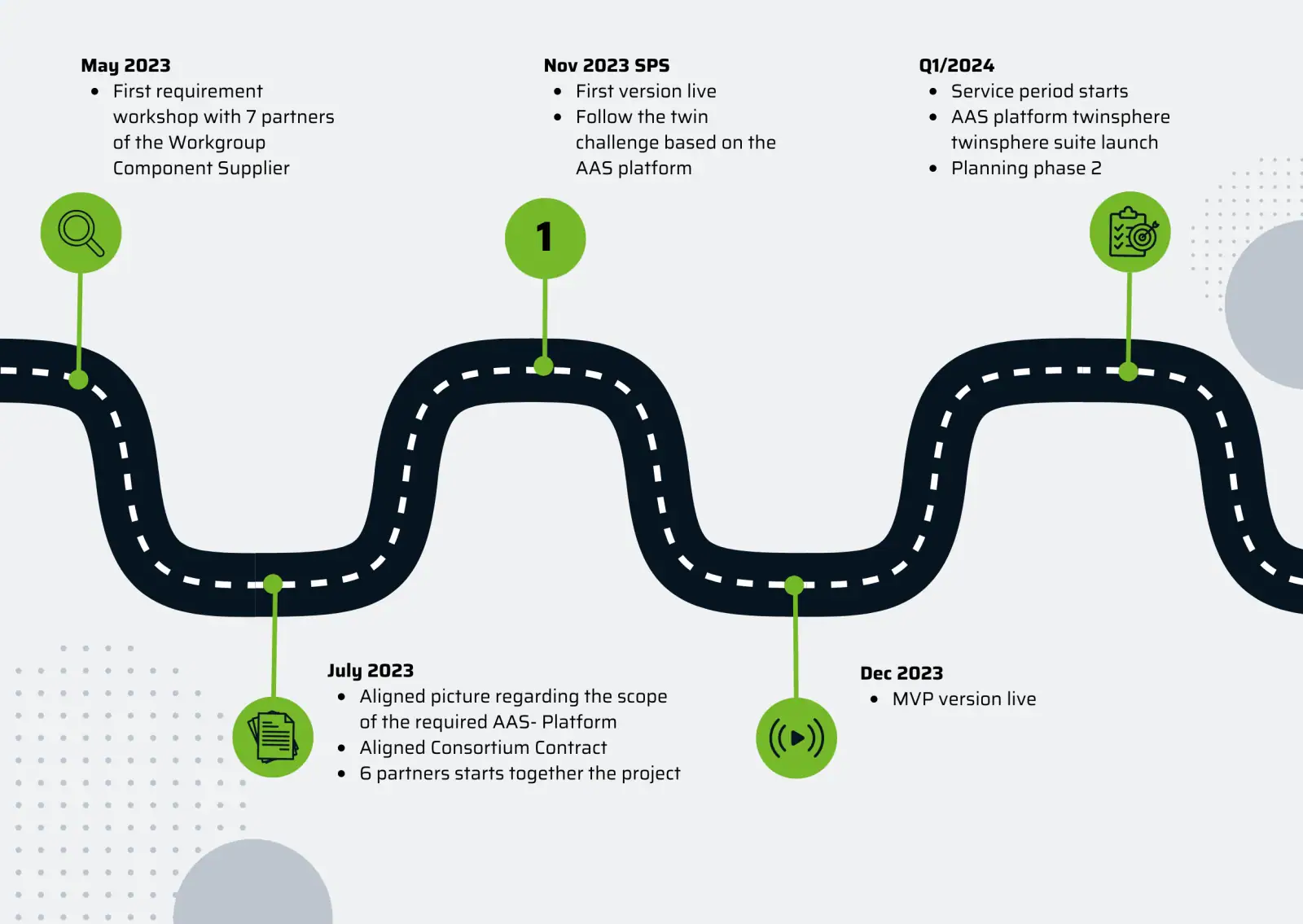

ROADMAP

BETTER

TOGETHER

What makes Twinsphere stand out is how it was created. Rather than being developed by a single vendor, the solution emerged from collaboration within the Open Industry 4.0 Alliance (OI4). The Component Supplier Workgroup brought together member companies with different requirements and perspectives to design a platform that reflects real-world industrial needs.

This spirit of collaboration ensures that Twinsphere is not just technically robust but also broadly applicable. It embodies the core mission of OI4: to transform complexity into modular, interoperable solutions that can be applied across industries. Other members are invited to join this work: to contribute, benefit, and shape what comes next.

Twinsphere is more than a technical tool. It is a community achievement that helps industry players move beyond theory and into scalable, standards-based implementation.

INSIGHTS

AND Q&A

Why is VDI 2770 important for document management?

VDI 2770 establishes a standardized approach for structuring and exchanging digital documentation, ensuring consistency and accessibility across industries. By providing machine-readable, structured formats, it streamlines document handling, reduces manual effort, and enhances compliance with regulatory and industry requirements. Companies can efficiently manage and distribute technical documentation, making information readily available for suppliers, customers, and regulatory bodies.

How does the Digital Product Passport (DPP) impact businesses?

The Digital Product Passport (DPP) enhances transparency by providing comprehensive, standardized product data throughout the entire lifecycle. It supports regulatory compliance by ensuring that companies can track and report key sustainability and technical information, such as carbon footprint or material composition. DPP also improves supply chain efficiency by enabling seamless data sharing between manufacturers, suppliers, and end users, ultimately fostering circular economy practices and sustainable production.

Why is interoperability crucial in digital ecosystems?

Interoperability ensures seamless integration between different digital systems, reducing complexity and enabling efficient data exchange. Standardized APIs, administration shells, and event-driven architectures allow various platforms to communicate without requiring extensive customization. This facilitates automation, enhances collaboration across industries, and supports emerging digital use cases like Digital Twins and smart manufacturing. By fostering a connected digital landscape, interoperability drives innovation, cost savings, and operational efficiency.